18 Years Factory File Transfer Cable - CY Screened Multicore Control Cable – AIPU

18 Years Factory File Transfer Cable - CY Screened Multicore Control Cable – AIPU Detail:

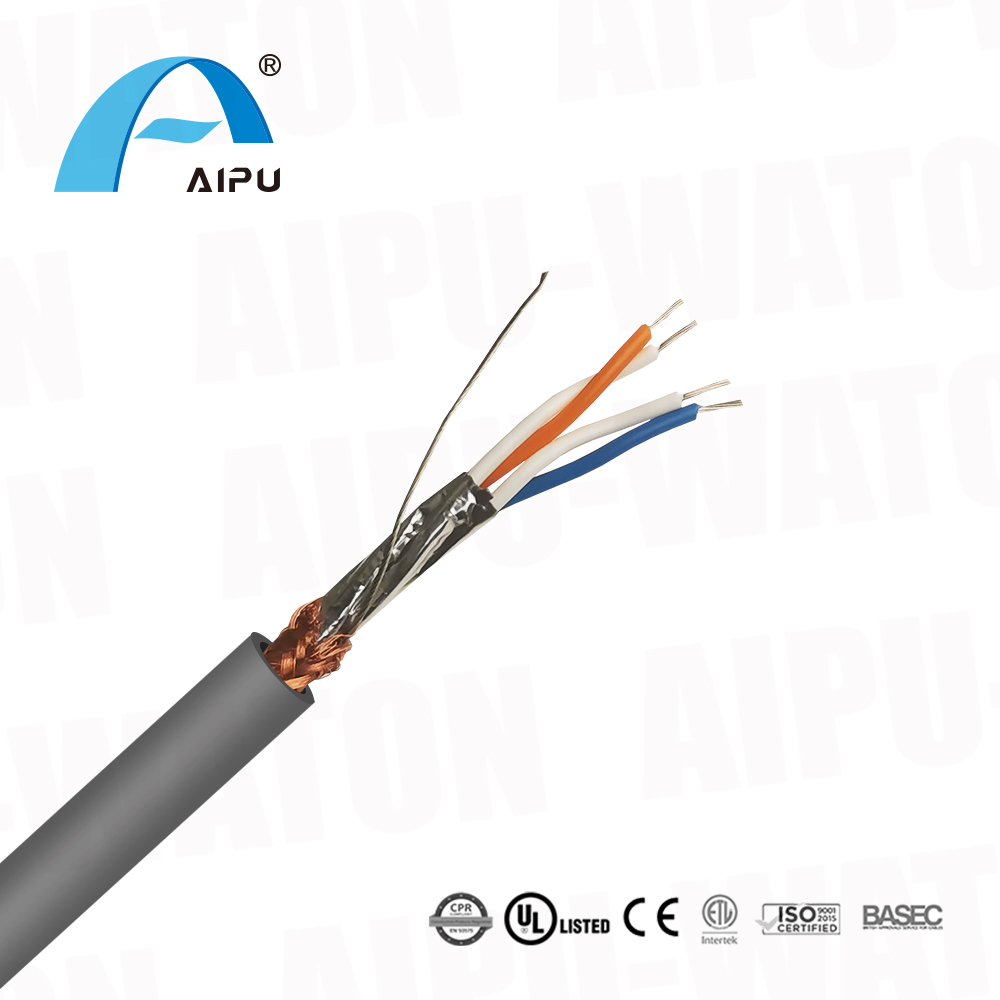

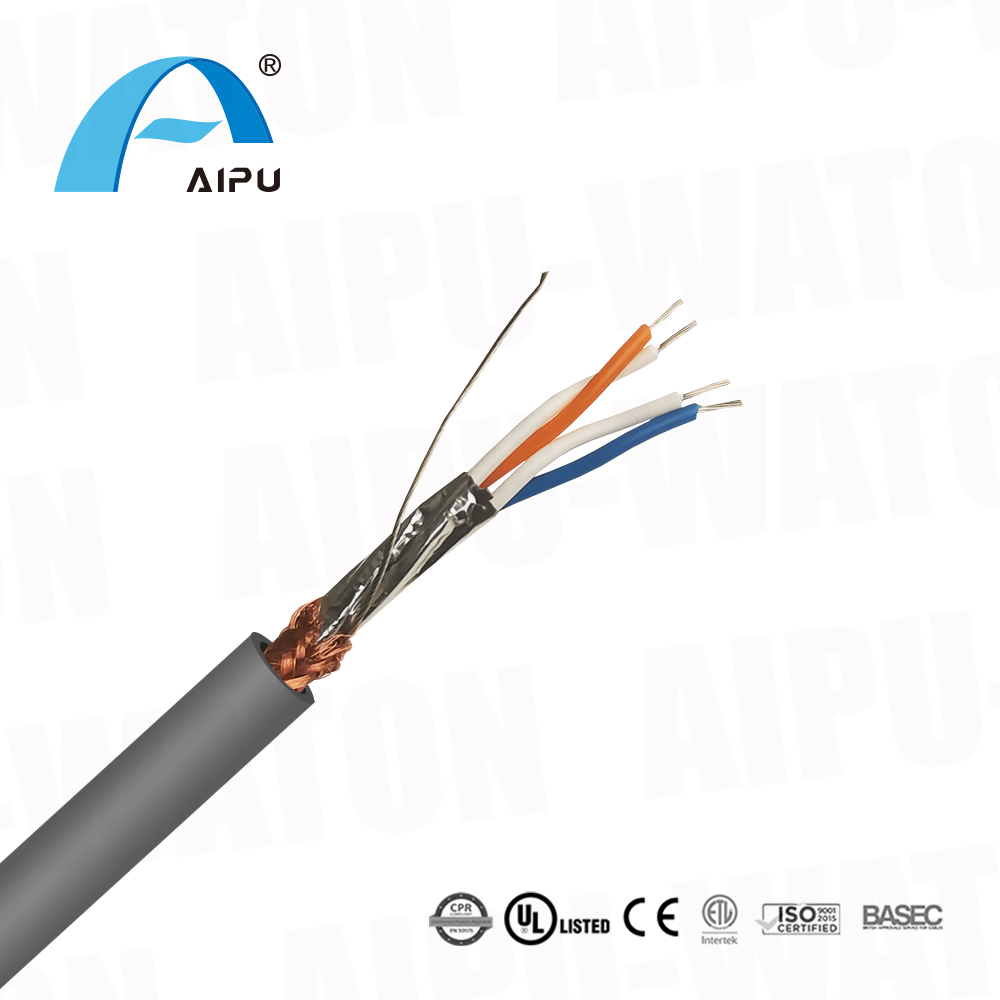

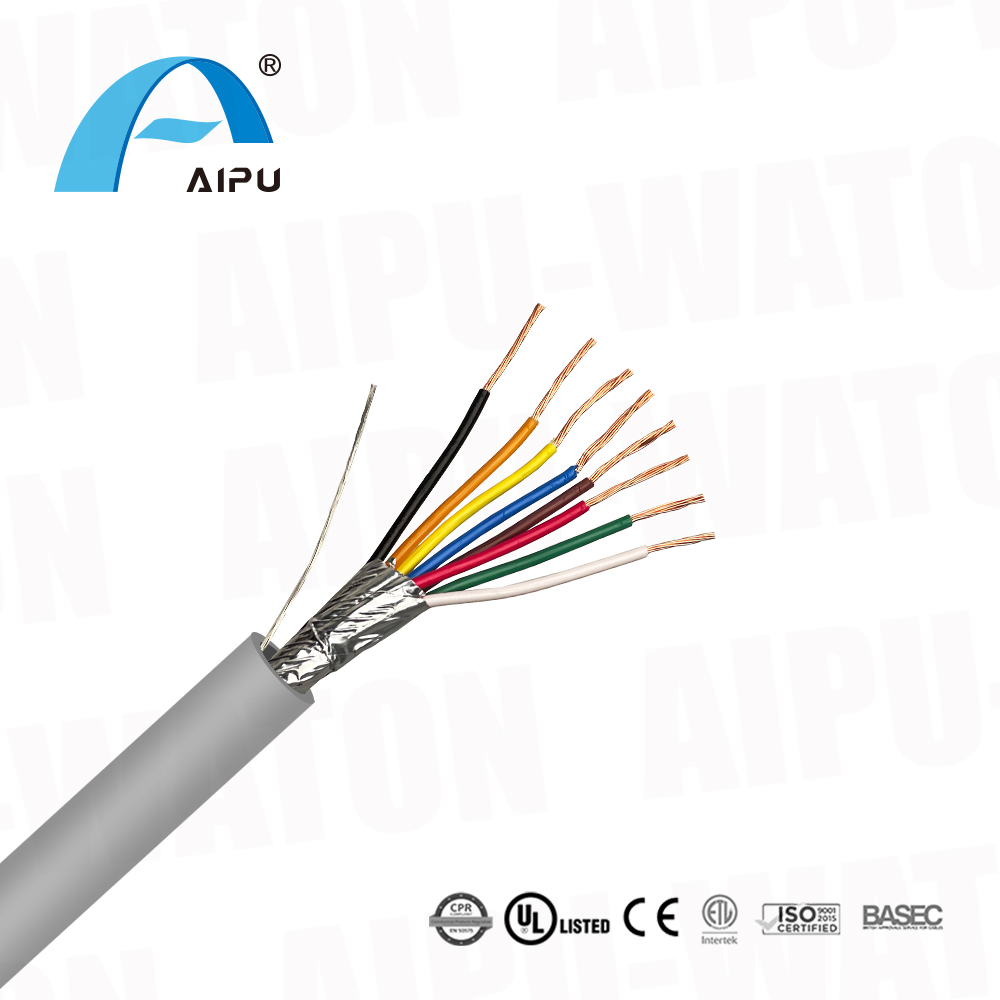

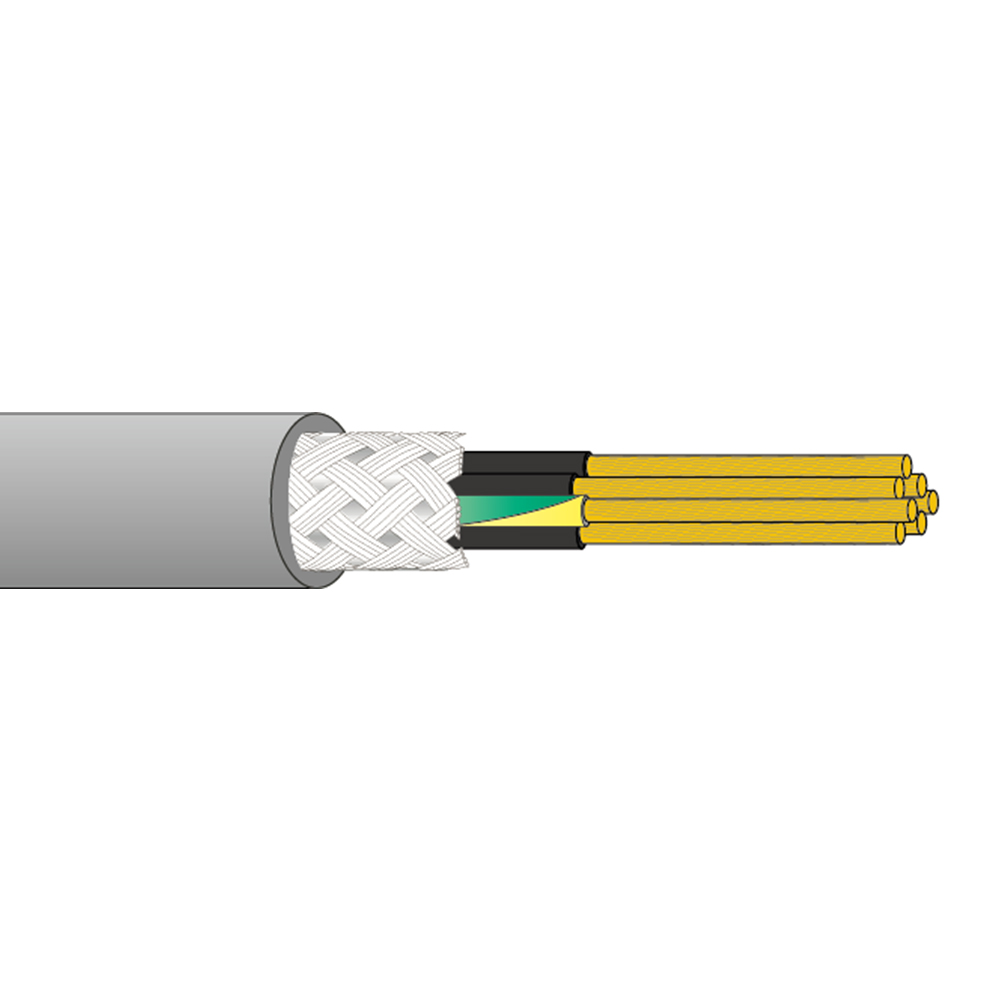

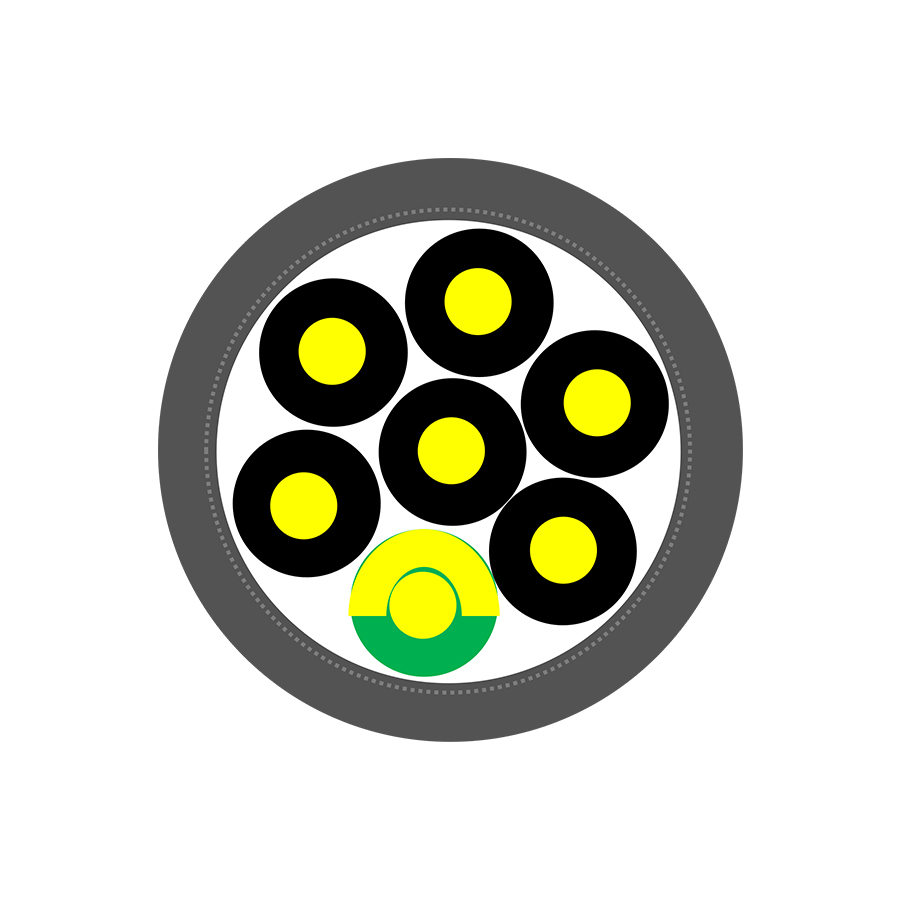

Constructions

1. Conductor: Class 5 Oxygen Free Copper

2. Insulation: PVC/LSZH

3. Identification:

Black Cores with White Number

1pc Green/Yellow Core

4. Screen: Tinned Copper Wire Braided

5. Sheath: PVC/LSZH (Grey)

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 70℃

Rated Voltage: 300/300V

Reference Standards

BS6500

BS EN 60228

BS EN 50525-2-11

BS EN 50363-3

BS EN 50363-7

BS EN 50363-4-1

BS EN 50363-8

RoHS Directives

IEC60332-1

0.5mm2

|

Part No. |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.6 |

39 |

|

CY 3×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.9 |

39 |

|

CY 4×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

39 |

|

CY 5×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

39 |

|

CY 7×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

39 |

|

CY 8×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

8 |

39 |

|

CY 10×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

0.6 |

39 |

|

CY 12×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

9.9 |

39 |

|

CY 16×0.5 |

16/0.20 |

0.4 |

1.1 |

TC Braided |

11 |

39 |

0.75mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6 |

26 |

|

CY 3×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

26 |

|

CY 4×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

26 |

|

CY 5×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

7.33 |

26 |

|

CY 7×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

26 |

|

CY 8×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

26 |

|

CY 10×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

10.2 |

26 |

|

CY 12×0.75 |

24/0.20 |

0.4 |

1 |

TC Braided |

10.8 |

26 |

|

CY 16×0.75 |

24/0.20 |

0.4 |

1.1 |

TC Braided |

12 |

26 |

1.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.4 |

19.5 |

|

CY 3×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

19.5 |

|

CY 4×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

19.5 |

|

CY 5×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

19.5 |

|

CY 7×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

19.5 |

|

CY 8×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

9.8 |

19.5 |

|

CY 10×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

11.2 |

19.5 |

|

CY 12×1.0 |

32/0.20 |

0.4 |

1.1 |

TC Braided |

11.7 |

19.5 |

|

CY 16×1.0 |

32/0.20 |

0.4 |

1.2 |

TC Braided |

13.1 |

19.5 |

1.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7 |

13.3 |

|

CY 3×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7.4 |

13.3 |

|

CY 4×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

8.2 |

13.3 |

|

CY 5×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

9.1 |

13.3 |

|

CY 7×1.5 |

30/0.25 |

0.4 |

1 |

TC Braided |

10 |

13.3 |

|

CY 8×1.5 |

30/0.25 |

0.4 |

1.1 |

TC Braided |

11 |

13.3 |

|

CY 10×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

12.8 |

13.3 |

|

CY 12×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

13.2 |

13.3 |

|

CY 16×1.5 |

30/0.25 |

0.4 |

1.3 |

TC Braided |

14.7 |

13.3 |

2.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

8.2 |

7.98 |

|

CY 3×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

9.1 |

7.98 |

|

CY 4×2.5 |

48/0.25 |

0.5 |

1 |

TC Braided |

10.1 |

7.98 |

|

CY 5×2.5 |

48/0.25 |

0.5 |

1.1 |

TC Braided |

11.1 |

7.98 |

|

CY 7×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.2 |

7.98 |

|

CY 8×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.8 |

7.98 |

|

CY 10×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15 |

7.98 |

|

CY 12×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15.6 |

7.98 |

|

CY 16×2.5 |

48/0.25 |

0.5 |

1.4 |

TC Braided |

17.3 |

7.98 |

4.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 3×4.0 |

56/0.30 |

0.6 |

1.1 |

TC Braided |

11.4 |

4.95 |

|

CY 4×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

12.4 |

4.95 |

|

CY 5×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

13.5 |

4.95 |

|

CY 7×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

14.8 |

4.95 |

|

CY 8×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

16.0 |

4.95 |

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for 18 Years Factory File Transfer Cable - CY Screened Multicore Control Cable – AIPU , The product will supply to all over the world, such as: Kenya, Kuala Lumpur, Estonia, We are confident that we are able to provide you with opportunities and will be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of products that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.