Factory Outlets For Solid Conductor Cable - CY Screened Multicore Control Cable – AIPU

Factory Outlets For Solid Conductor Cable - CY Screened Multicore Control Cable – AIPU Detail:

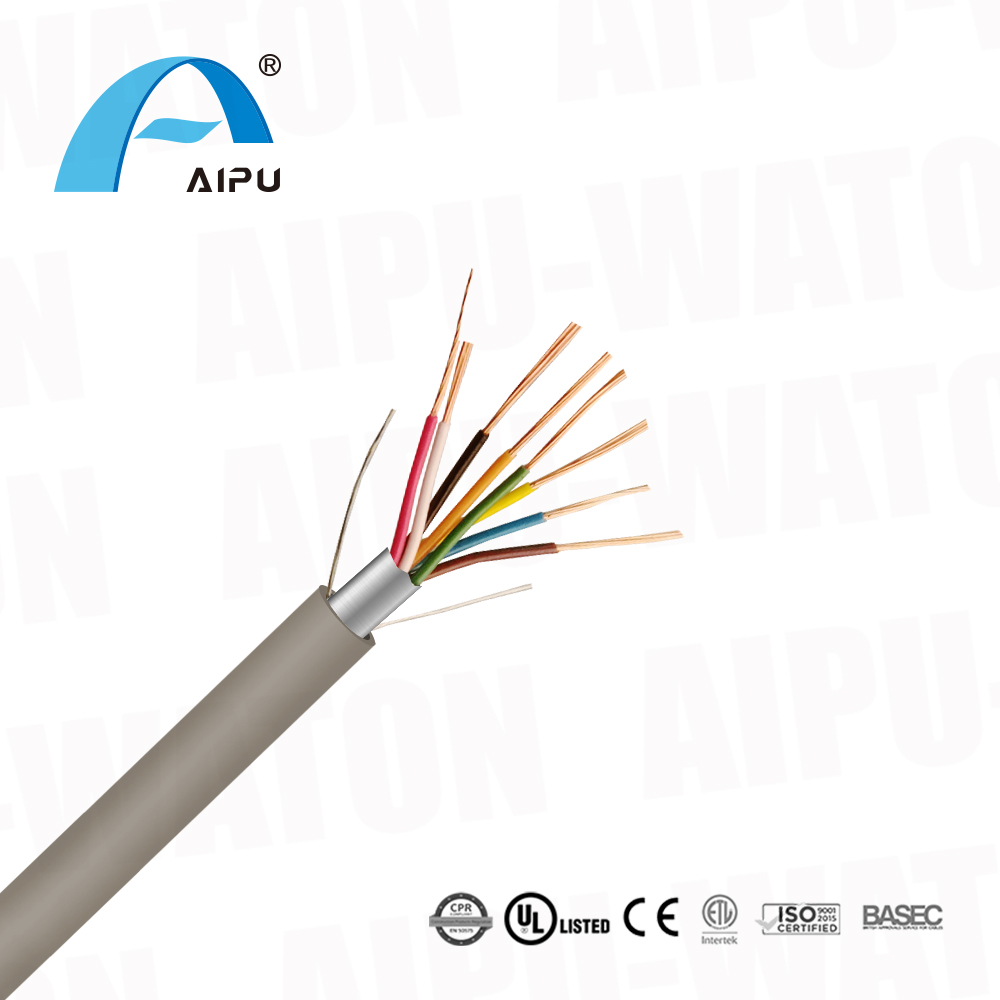

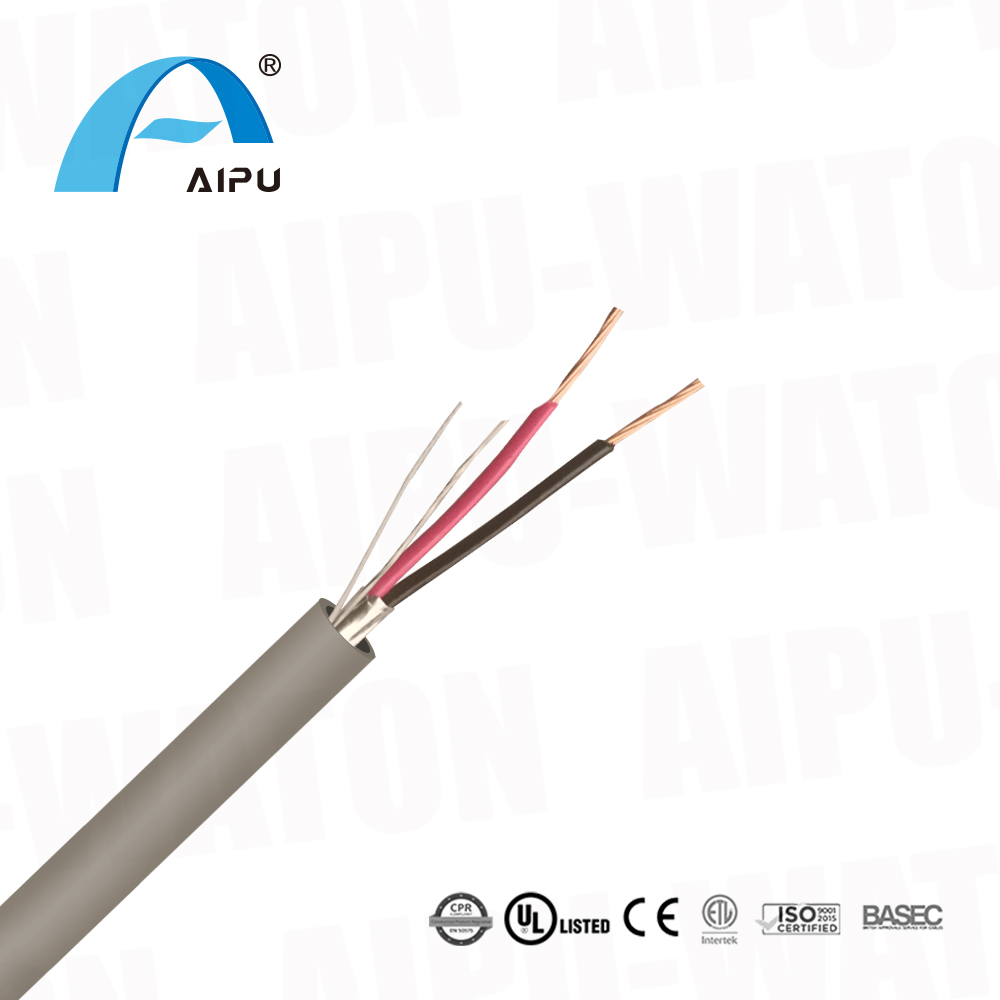

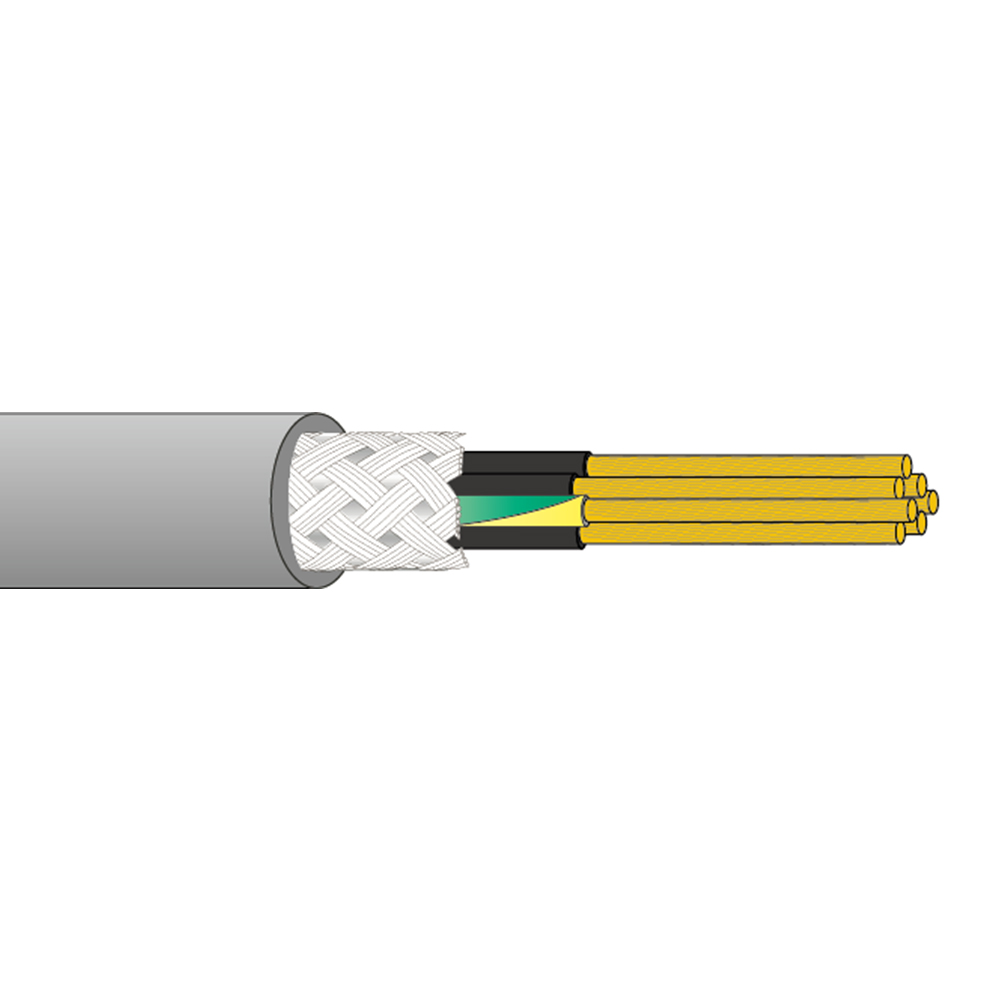

Constructions

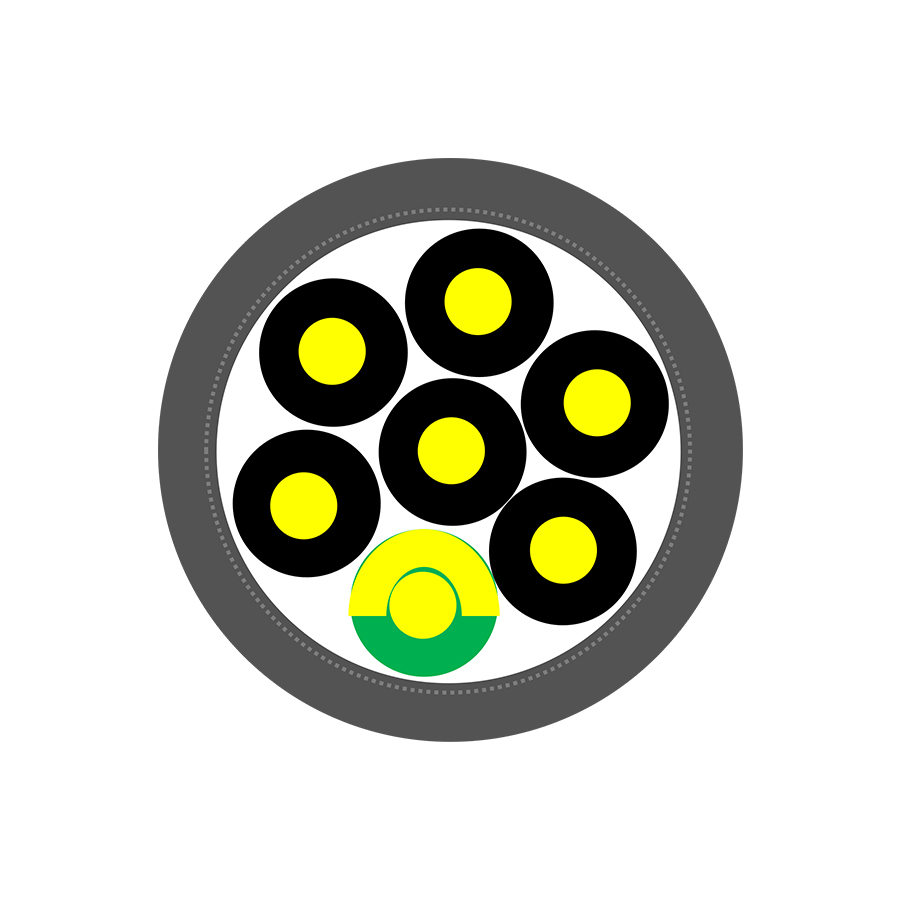

1. Conductor: Class 5 Oxygen Free Copper

2. Insulation: PVC/LSZH

3. Identification:

Black Cores with White Number

1pc Green/Yellow Core

4. Screen: Tinned Copper Wire Braided

5. Sheath: PVC/LSZH (Grey)

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 70℃

Rated Voltage: 300/300V

Reference Standards

BS6500

BS EN 60228

BS EN 50525-2-11

BS EN 50363-3

BS EN 50363-7

BS EN 50363-4-1

BS EN 50363-8

RoHS Directives

IEC60332-1

0.5mm2

|

Part No. |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.6 |

39 |

|

CY 3×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.9 |

39 |

|

CY 4×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

39 |

|

CY 5×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

39 |

|

CY 7×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

39 |

|

CY 8×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

8 |

39 |

|

CY 10×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

0.6 |

39 |

|

CY 12×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

9.9 |

39 |

|

CY 16×0.5 |

16/0.20 |

0.4 |

1.1 |

TC Braided |

11 |

39 |

0.75mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6 |

26 |

|

CY 3×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

26 |

|

CY 4×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

26 |

|

CY 5×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

7.33 |

26 |

|

CY 7×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

26 |

|

CY 8×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

26 |

|

CY 10×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

10.2 |

26 |

|

CY 12×0.75 |

24/0.20 |

0.4 |

1 |

TC Braided |

10.8 |

26 |

|

CY 16×0.75 |

24/0.20 |

0.4 |

1.1 |

TC Braided |

12 |

26 |

1.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.4 |

19.5 |

|

CY 3×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

19.5 |

|

CY 4×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

19.5 |

|

CY 5×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

19.5 |

|

CY 7×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

19.5 |

|

CY 8×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

9.8 |

19.5 |

|

CY 10×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

11.2 |

19.5 |

|

CY 12×1.0 |

32/0.20 |

0.4 |

1.1 |

TC Braided |

11.7 |

19.5 |

|

CY 16×1.0 |

32/0.20 |

0.4 |

1.2 |

TC Braided |

13.1 |

19.5 |

1.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7 |

13.3 |

|

CY 3×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7.4 |

13.3 |

|

CY 4×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

8.2 |

13.3 |

|

CY 5×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

9.1 |

13.3 |

|

CY 7×1.5 |

30/0.25 |

0.4 |

1 |

TC Braided |

10 |

13.3 |

|

CY 8×1.5 |

30/0.25 |

0.4 |

1.1 |

TC Braided |

11 |

13.3 |

|

CY 10×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

12.8 |

13.3 |

|

CY 12×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

13.2 |

13.3 |

|

CY 16×1.5 |

30/0.25 |

0.4 |

1.3 |

TC Braided |

14.7 |

13.3 |

2.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

8.2 |

7.98 |

|

CY 3×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

9.1 |

7.98 |

|

CY 4×2.5 |

48/0.25 |

0.5 |

1 |

TC Braided |

10.1 |

7.98 |

|

CY 5×2.5 |

48/0.25 |

0.5 |

1.1 |

TC Braided |

11.1 |

7.98 |

|

CY 7×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.2 |

7.98 |

|

CY 8×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.8 |

7.98 |

|

CY 10×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15 |

7.98 |

|

CY 12×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15.6 |

7.98 |

|

CY 16×2.5 |

48/0.25 |

0.5 |

1.4 |

TC Braided |

17.3 |

7.98 |

4.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 3×4.0 |

56/0.30 |

0.6 |

1.1 |

TC Braided |

11.4 |

4.95 |

|

CY 4×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

12.4 |

4.95 |

|

CY 5×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

13.5 |

4.95 |

|

CY 7×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

14.8 |

4.95 |

|

CY 8×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

16.0 |

4.95 |

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Factory Outlets For Solid Conductor Cable - CY Screened Multicore Control Cable – AIPU , The product will supply to all over the world, such as: Luxembourg, Iraq, Greece, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.