Leading Manufacturer For Structured Cable Systems - CY Screened Multicore Control Cable – AIPU

Leading Manufacturer For Structured Cable Systems - CY Screened Multicore Control Cable – AIPU Detail:

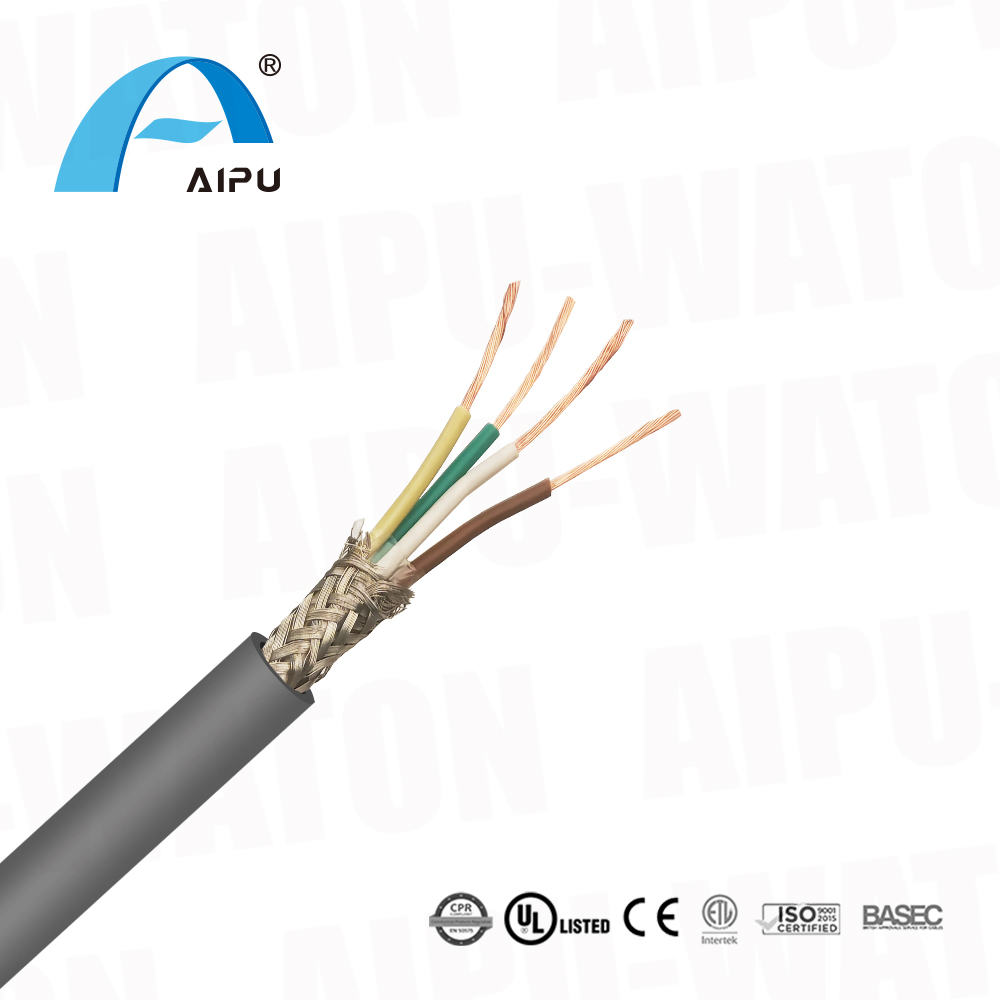

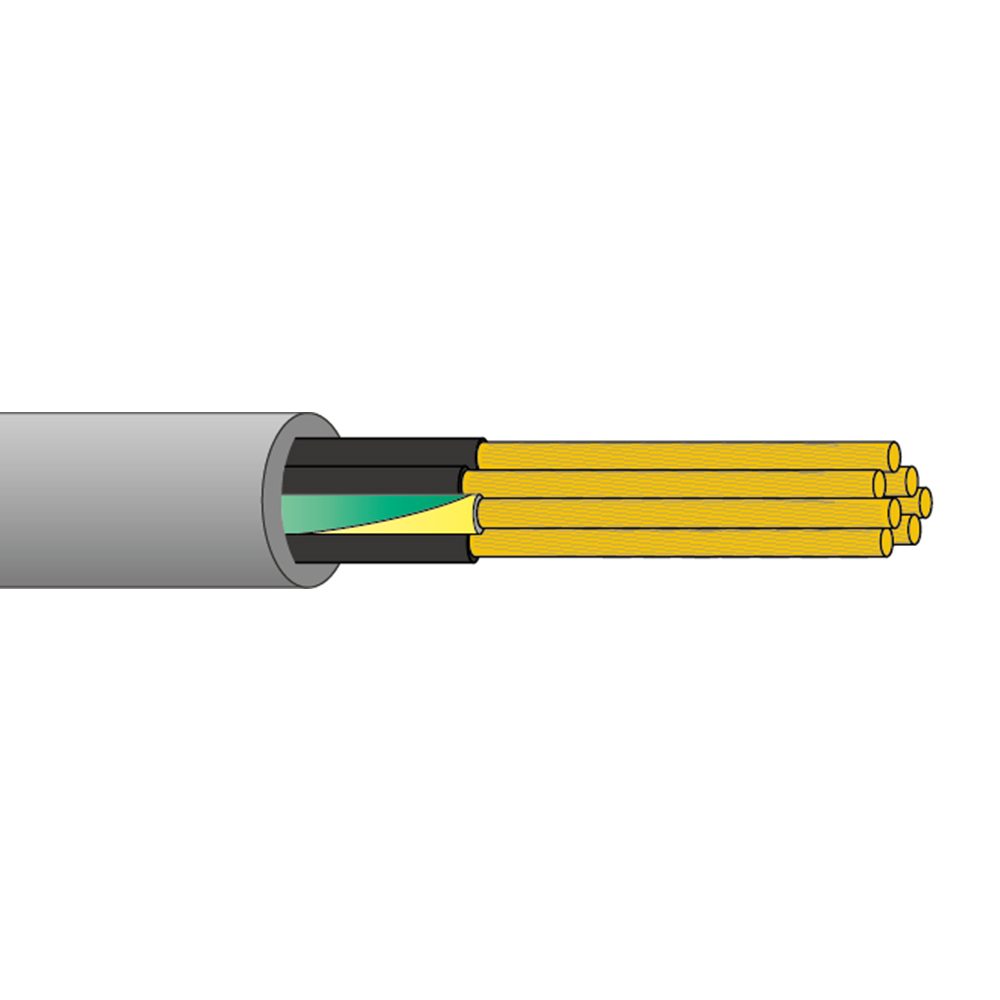

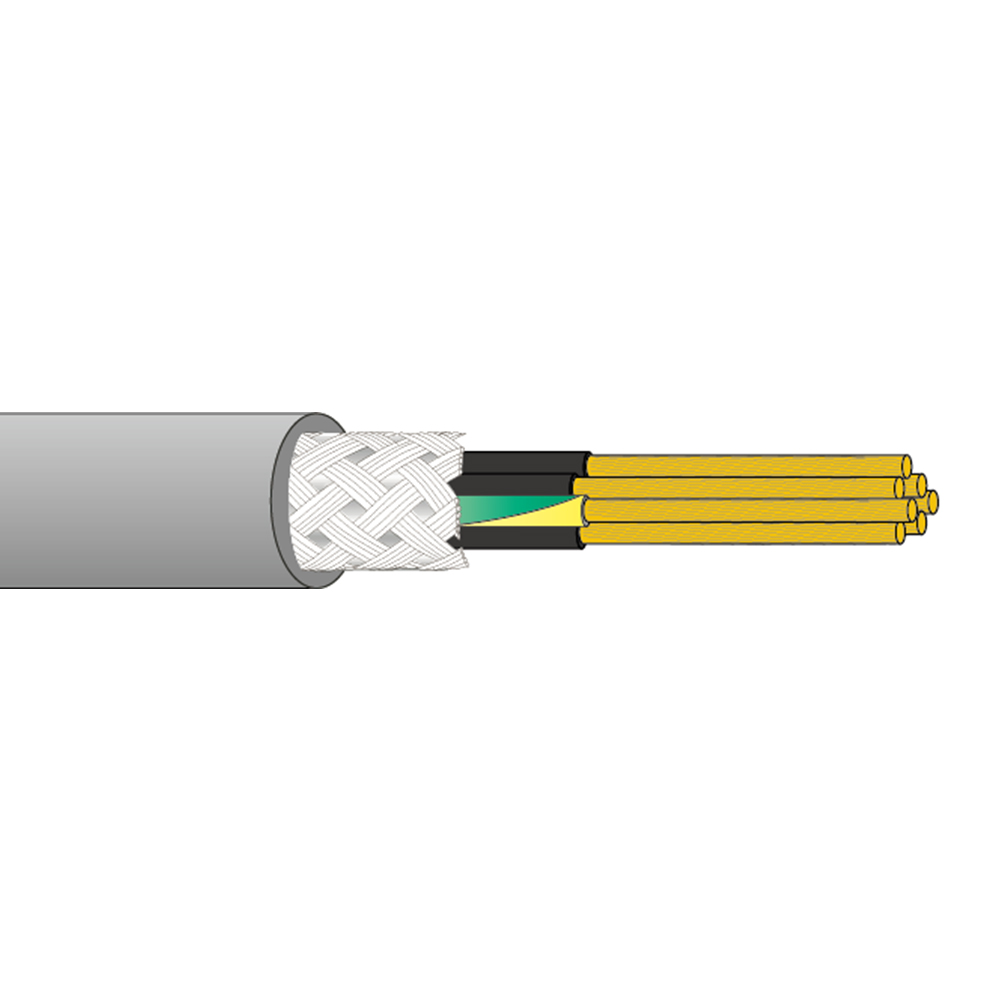

Constructions

1. Conductor: Class 5 Oxygen Free Copper

2. Insulation: PVC/LSZH

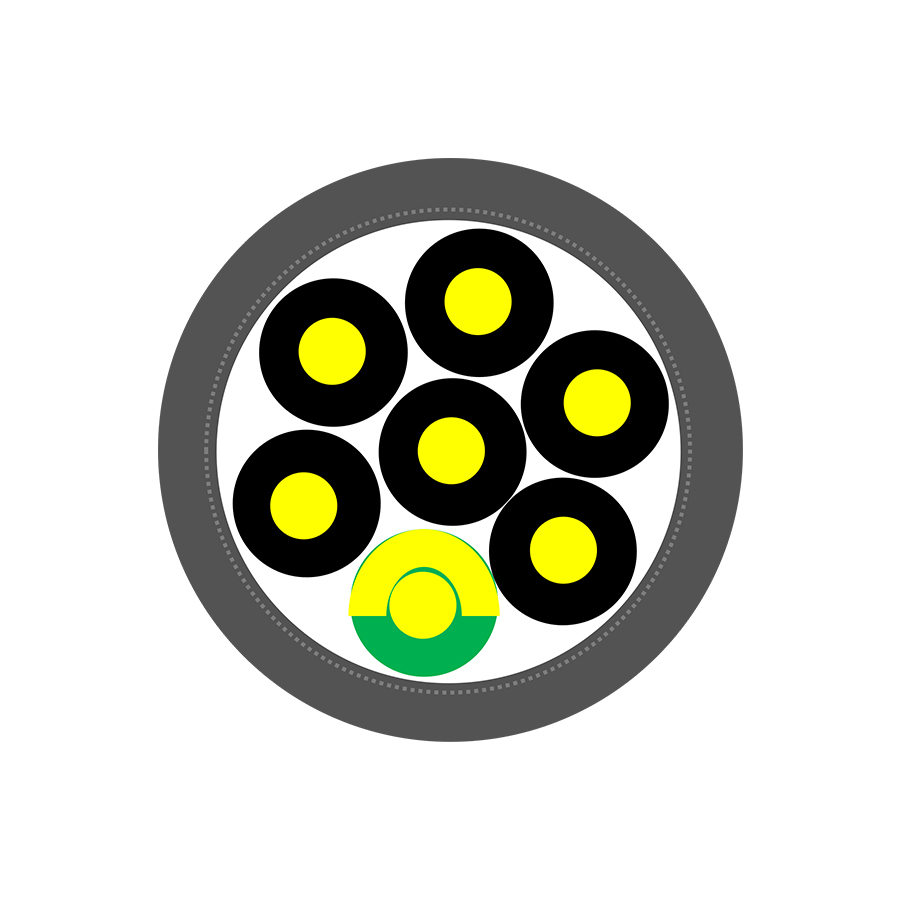

3. Identification:

Black Cores with White Number

1pc Green/Yellow Core

4. Screen: Tinned Copper Wire Braided

5. Sheath: PVC/LSZH (Grey)

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 70℃

Rated Voltage: 300/300V

Reference Standards

BS6500

BS EN 60228

BS EN 50525-2-11

BS EN 50363-3

BS EN 50363-7

BS EN 50363-4-1

BS EN 50363-8

RoHS Directives

IEC60332-1

0.5mm2

|

Part No. |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.6 |

39 |

|

CY 3×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.9 |

39 |

|

CY 4×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

39 |

|

CY 5×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

39 |

|

CY 7×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

39 |

|

CY 8×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

8 |

39 |

|

CY 10×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

0.6 |

39 |

|

CY 12×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

9.9 |

39 |

|

CY 16×0.5 |

16/0.20 |

0.4 |

1.1 |

TC Braided |

11 |

39 |

0.75mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6 |

26 |

|

CY 3×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

26 |

|

CY 4×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

26 |

|

CY 5×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

7.33 |

26 |

|

CY 7×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

26 |

|

CY 8×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

26 |

|

CY 10×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

10.2 |

26 |

|

CY 12×0.75 |

24/0.20 |

0.4 |

1 |

TC Braided |

10.8 |

26 |

|

CY 16×0.75 |

24/0.20 |

0.4 |

1.1 |

TC Braided |

12 |

26 |

1.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.4 |

19.5 |

|

CY 3×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

19.5 |

|

CY 4×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

19.5 |

|

CY 5×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

19.5 |

|

CY 7×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

19.5 |

|

CY 8×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

9.8 |

19.5 |

|

CY 10×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

11.2 |

19.5 |

|

CY 12×1.0 |

32/0.20 |

0.4 |

1.1 |

TC Braided |

11.7 |

19.5 |

|

CY 16×1.0 |

32/0.20 |

0.4 |

1.2 |

TC Braided |

13.1 |

19.5 |

1.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7 |

13.3 |

|

CY 3×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7.4 |

13.3 |

|

CY 4×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

8.2 |

13.3 |

|

CY 5×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

9.1 |

13.3 |

|

CY 7×1.5 |

30/0.25 |

0.4 |

1 |

TC Braided |

10 |

13.3 |

|

CY 8×1.5 |

30/0.25 |

0.4 |

1.1 |

TC Braided |

11 |

13.3 |

|

CY 10×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

12.8 |

13.3 |

|

CY 12×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

13.2 |

13.3 |

|

CY 16×1.5 |

30/0.25 |

0.4 |

1.3 |

TC Braided |

14.7 |

13.3 |

2.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

8.2 |

7.98 |

|

CY 3×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

9.1 |

7.98 |

|

CY 4×2.5 |

48/0.25 |

0.5 |

1 |

TC Braided |

10.1 |

7.98 |

|

CY 5×2.5 |

48/0.25 |

0.5 |

1.1 |

TC Braided |

11.1 |

7.98 |

|

CY 7×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.2 |

7.98 |

|

CY 8×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.8 |

7.98 |

|

CY 10×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15 |

7.98 |

|

CY 12×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15.6 |

7.98 |

|

CY 16×2.5 |

48/0.25 |

0.5 |

1.4 |

TC Braided |

17.3 |

7.98 |

4.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 3×4.0 |

56/0.30 |

0.6 |

1.1 |

TC Braided |

11.4 |

4.95 |

|

CY 4×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

12.4 |

4.95 |

|

CY 5×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

13.5 |

4.95 |

|

CY 7×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

14.8 |

4.95 |

|

CY 8×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

16.0 |

4.95 |

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Leading Manufacturer For Structured Cable Systems - CY Screened Multicore Control Cable – AIPU , The product will supply to all over the world, such as: Estonia, Juventus, Argentina, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!