For BMS, BUS, Industrial, Instrumentation Cable.

How To Identify Fake Patch Cords?

For professionals in the structured cabling industry, jumpers are a well-known and essential product. Serving as vital components within the management subsystem, jumpers facilitate interconnections between vertical mainframes and horizontal cabling subsystems in conjunction with patch panels. The quality of these jumpers directly influences the overall transmission performance of network links.

The Challenge of Cost-Saving on Jumpers

In the realm of low-voltage electrical installations, it’s common to encounter practitioners who opt for cost-saving measures. Some choose to use "hard wires" with crystal heads directly crimped on both ends, effectively bypassing the use of “factory-made gel-filled jumpers.” Let's delve into the distinction between these two approaches:

Materials Matter

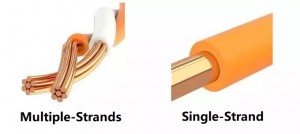

Jumpers, also referred to as patch cords, are typically utilized in environments that involve patch panels, cable management systems, and switches. Because these setups require numerous bends and twists, it's essential for the jumpers to be flexible enough to navigate complex pathways without compromising their integrity.

Jumpers made from multiple strands of fine copper wire are markedly more flexible than those constructed from single-strand hard wire. This inherent flexibility is just one of the advantages of using multi-strand soft wire in jumper construction.

Manufacturing Precision

The process of crimping crystal heads is familiar to professionals in the field; however, it can often present challenges. Issues can arise during the crimping of hard wires—broken or misaligned connections often occur due to the direct force exerted when a hard wire meets the gold pin. The consequences of improper crimping can lead to substantial damage to devices, particularly at critical junctures such as switch ports.

When crimping with multi-strand soft wire, the impact is distributed across the copper strands, resulting in a superior connection that promotes enhanced transmission performance. This method mitigates the risk of breakage or misalignment that is often seen with hard wire crimping.

The Importance of Tools

The choice of crimping tools is paramount. Crimping pliers can be found at various price points, ranging from a few dollars to several thousand, underscoring the significance of investing in high-quality tools that ensure reliable connections.

The Manufacturing Process of Factory-Made Gel-Filled Jumpers

Factory-made gel-filled jumpers undergo a meticulous manufacturing process. Advanced crimping jigs are utilized to guarantee precise crimping during production. Each assembled crystal head is positioned with the gold pin facing upwards in a dedicated fixture on a punch press. The crimping depth is finely tuned to ensure accuracy, with specifications typically maintained between 5.90 mm and 6.146 mm. After crimping, each jumper is tested, and only those that pass proceed to have gel injected for protective sheathing, securing the jumper connection.

Testing for Assurance

Typically, after crimping “hard wire” jumpers, users might plug them directly into devices, often performing only a basic continuity test. However, this approach does not adequately assess the performance of the jumper. A basic continuity tester merely indicates whether a connection exists, failing to consider the quality of the crimp or the effectiveness of the signal transmission.

In contrast, the production of factory-made gel-filled jumpers includes two rigorous rounds of testing. Initially, a continuity tester evaluates the quality of the connections. Only those that pass this preliminary assessment move on to the subsequent phase, which involves FLUKE testing to examine essential performance metrics such as insertion loss and return loss. Items that do not meet the stringent testing criteria are subject to rework, ensuring that only high-performing jumpers reach the market.

Conclusion

In summary, the choice of jumper—whether factory-made gel-filled or DIY hard wire—has significant implications on network performance. By prioritizing high-quality materials, precise manufacturing processes, and thorough testing, professionals in the structured cabling industry can ensure the reliability and efficiency of their networks. Investing in quality jumpers is not just a matter of performance; it’s essential for safeguarding the integrity of your entire network infrastructure.

Find ELV Cable Solution

Control Cables

Structured Cabling System

Network&Data, Fiber-Optic Cable, Patch Cord, Modules, Faceplate

2024 Exhibitions & Events Review

Apr.16th-18th, 2024 Middle-East-Energy in Dubai

Apr.16th-18th, 2024 Securika in Moscow

May.9th, 2024 NEW PRODUCTS & TECHNOLOGIES LAUNCH EVENT in Shanghai

Post time: Aug-16-2024