Popular Design For Elevator Cable - LiYcY Screened Multicore Control Cable – AIPU

Popular Design For Elevator Cable - LiYcY Screened Multicore Control Cable – AIPU Detail:

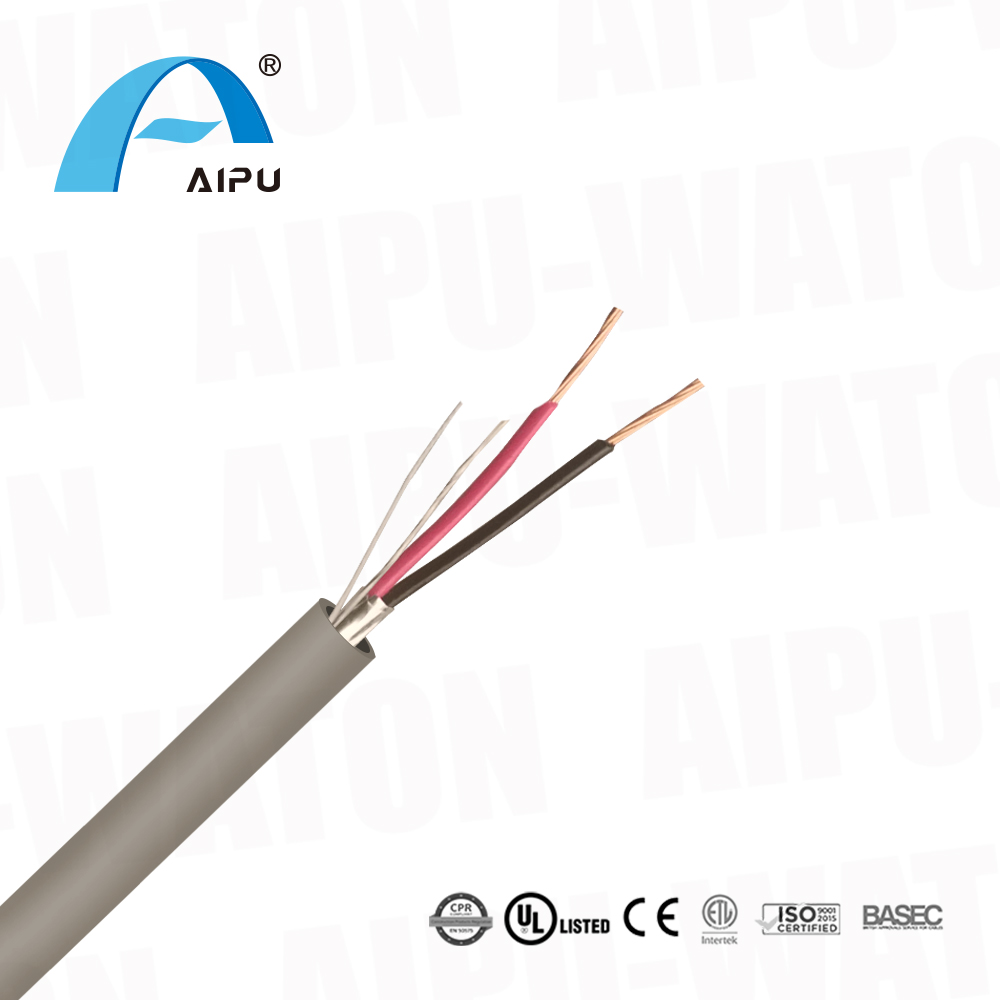

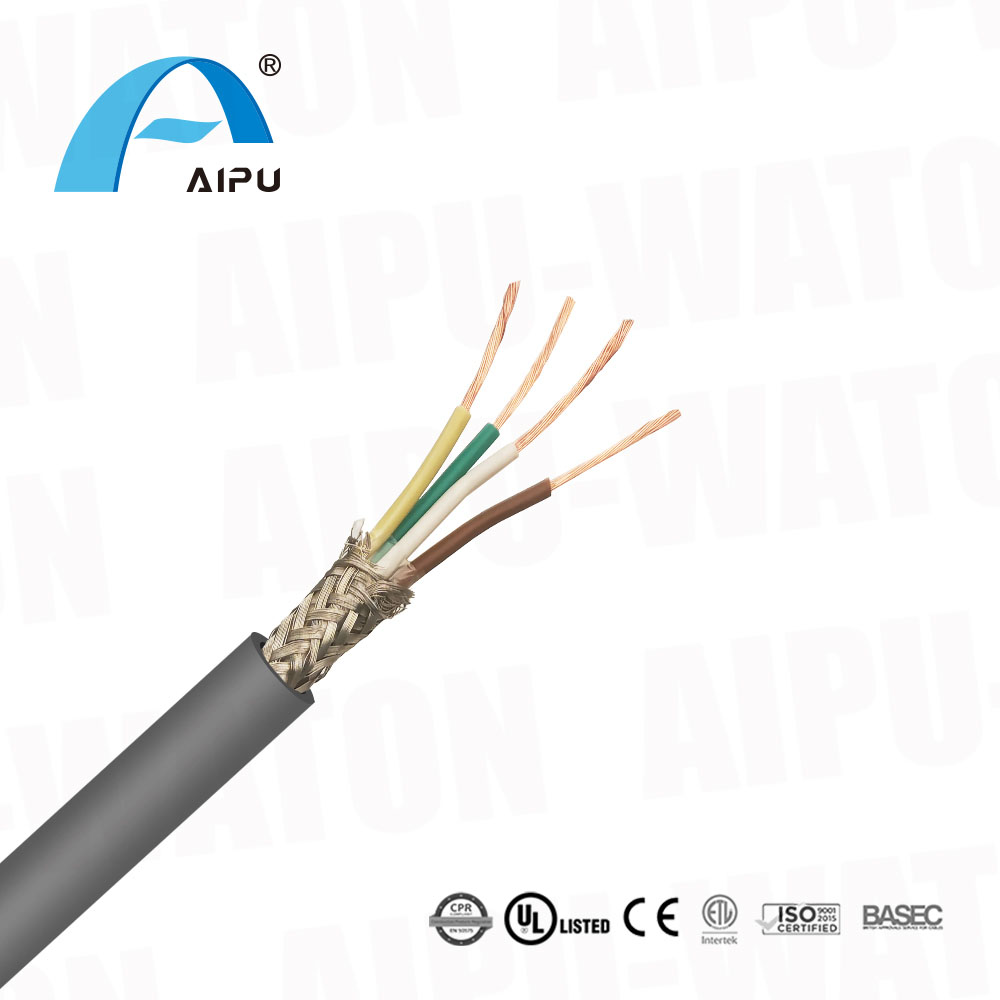

Constructions

1. Conductor: Class 5 Tinned Copper

2. Insulation: PVC

3. Identification: Colored

4. Cabling: Twisted Pair

5. Screen: Tinned Copper Wire Braided

6. Sheath: PVC

Installation Temperature: Above 0ºC

Operating Temperature: -15ºC ~ 70ºC

Reference Standards

VDE 0812

DIN 1704

VDE 0207

RoHS Directives

IEC60332-1

0.14mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×0.14 |

12/0.12 |

0.35 |

0.7 |

4.4 |

148 |

|

LiYcY 3×0.14 |

12/0.12 |

0.35 |

0.7 |

4.7 |

148 |

|

LiYcY 4×0.14 |

12/0.12 |

0.35 |

0.7 |

4.9 |

148 |

|

LiYcY 5×0.14 |

12/0.12 |

0.35 |

0.7 |

5.3 |

148 |

|

LiYcY 7×0.14 |

12/0.12 |

0.35 |

0.7 |

5.6 |

148 |

|

LiYcY 8×0.14 |

12/0.12 |

0.35 |

0.8 |

6.2 |

148 |

|

LiYcY 10×0.14 |

12/0.12 |

0.35 |

0.8 |

7 |

148 |

|

LiYcY 12×0.14 |

12/0.12 |

0.35 |

0.8 |

7.3 |

148 |

|

LiYcY 14×0.14 |

12/0.12 |

0.35 |

0.8 |

7.5 |

148 |

0.25mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×0.25 |

14/0.15 |

0.4 |

0.7 |

4.8 |

79.9 |

|

LiYcY 3×0.25 |

14/0.15 |

0.4 |

0.7 |

5.1 |

79.9 |

|

LiYcY 4×0.25 |

14/0.15 |

0.4 |

0.7 |

5.4 |

79.9 |

|

LiYcY 5×0.25 |

14/0.15 |

0.4 |

0.7 |

5.8 |

79.9 |

|

LiYcY 7×0.25 |

14/0.15 |

0.4 |

0.8 |

6.4 |

79.9 |

|

LiYcY 8×0.25 |

14/0.15 |

0.4 |

0.8 |

6.8 |

79.9 |

|

LiYcY 10×0.25 |

14/0.15 |

0.4 |

0.8 |

7.8 |

79.9 |

|

LiYcY 12×0.25 |

14/0.15 |

0.4 |

0.8 |

8.1 |

79.9 |

|

LiYcY 14×0.25 |

14/0.15 |

0.4 |

0.8 |

8.2 |

79.9 |

0.34mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×0.34 |

20/0.15 |

0.4 |

0.7 |

5.2 |

57 |

|

LiYcY 3×0.34 |

20/0.15 |

0.4 |

0.7 |

5.5 |

57 |

|

LiYcY 4×0.34 |

20/0.15 |

0.4 |

0.7 |

5.9 |

57 |

|

LiYcY 5×0.34 |

20/0.15 |

0.4 |

0.7 |

6.3 |

57 |

|

LiYcY 7×0.34 |

20/0.15 |

0.4 |

0.7 |

6.8 |

57 |

|

LiYcY 8×0.34 |

20/0.15 |

0.4 |

0.8 |

7.5 |

57 |

|

LiYcY 10×0.34 |

20/0.15 |

0.4 |

0.8 |

8.6 |

57 |

|

LiYcY 12×0.34 |

20/0.15 |

0.4 |

0.8 |

9.1 |

57 |

|

LiYcY 14×0.34 |

20/0.15 |

0.4 |

0.8 |

9.5 |

57 |

0.50mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×0.5 |

16/0.20 |

0.45 |

0.7 |

5.6 |

39 |

|

LiYcY 3×0.5 |

16/0.20 |

0.45 |

0.7 |

6 |

39 |

|

LiYcY 4×0.5 |

16/0.20 |

0.45 |

0.7 |

6.4 |

39 |

|

LiYcY 5×0.5 |

16/0.20 |

0.45 |

0.7 |

6.9 |

39 |

|

LiYcY 7×0.5 |

16/0.20 |

0.45 |

0.8 |

7.6 |

39 |

|

LiYcY 8×0.5 |

16/0.20 |

0.45 |

0.8 |

8.2 |

39 |

|

LiYcY 10×0.5 |

16/0.20 |

0.45 |

0.8 |

9.8 |

39 |

|

LiYcY 12×0.5 |

16/0.20 |

0.45 |

0.8 |

10.2 |

39 |

|

LiYcY 14×0.5 |

16/0.20 |

0.45 |

0.9 |

10.6 |

39 |

0.75mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×0.75 |

24/0.20 |

0.5 |

0.8 |

6.4 |

26 |

|

LiYcY 3×0.75 |

24/0.20 |

0.5 |

0.8 |

6.8 |

26 |

|

LiYcY 4×0.75 |

24/0.20 |

0.5 |

0.8 |

7.3 |

26 |

|

LiYcY 5×0.75 |

24/0.20 |

0.5 |

0.8 |

7.9 |

26 |

|

LiYcY 7×0.75 |

24/0.20 |

0.5 |

0.8 |

8.5 |

26 |

|

LiYcY 8×0.75 |

24/0.20 |

0.5 |

0.9 |

9.4 |

26 |

|

LiYcY 10×0.75 |

24/0.20 |

0.5 |

0.9 |

11 |

26 |

|

LiYcY 12×0.75 |

24/0.20 |

0.5 |

0.9 |

11.4 |

26 |

|

LiYcY 14×0.75 |

24/0.20 |

0.5 |

1 |

12.1 |

26 |

1.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×1.0 |

32/0.20 |

0.6 |

0.8 |

7.2 |

19.5 |

|

LiYcY 3×1.0 |

32/0.20 |

0.6 |

0.8 |

7.7 |

19.5 |

|

LiYcY 4×1.0 |

32/0.20 |

0.6 |

0.8 |

8.3 |

19.5 |

|

LiYcY 5×1.0 |

32/0.20 |

0.6 |

0.8 |

9.2 |

19.5 |

|

LiYcY 7×1.0 |

32/0.20 |

0.6 |

0.9 |

10.3 |

19.5 |

1.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Diameter (mm) |

Max. DCR at 20℃ (Ω/km) |

|

LiYcY 2×1.5 |

30/0.25 |

0.6 |

0.8 |

7.8 |

13.3 |

|

LiYcY 3×1.5 |

30/0.25 |

0.6 |

0.8 |

8.4 |

13.3 |

|

LiYcY 4×1.5 |

30/0.25 |

0.6 |

0.8 |

9.2 |

13.3 |

|

LiYcY 5×1.5 |

30/0.25 |

0.6 |

0.9 |

10.2 |

13.3 |

|

LiYcY 7×1.5 |

30/0.25 |

0.6 |

1 |

11 |

13.3 |

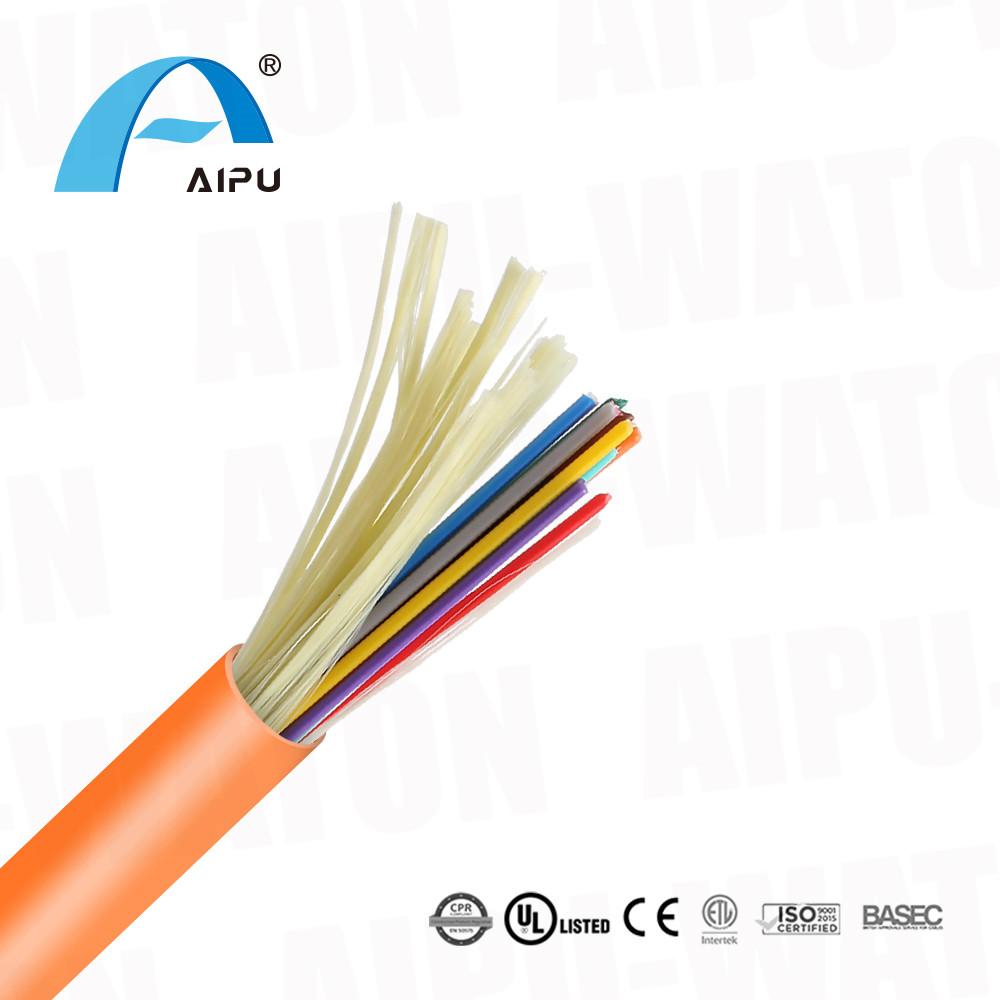

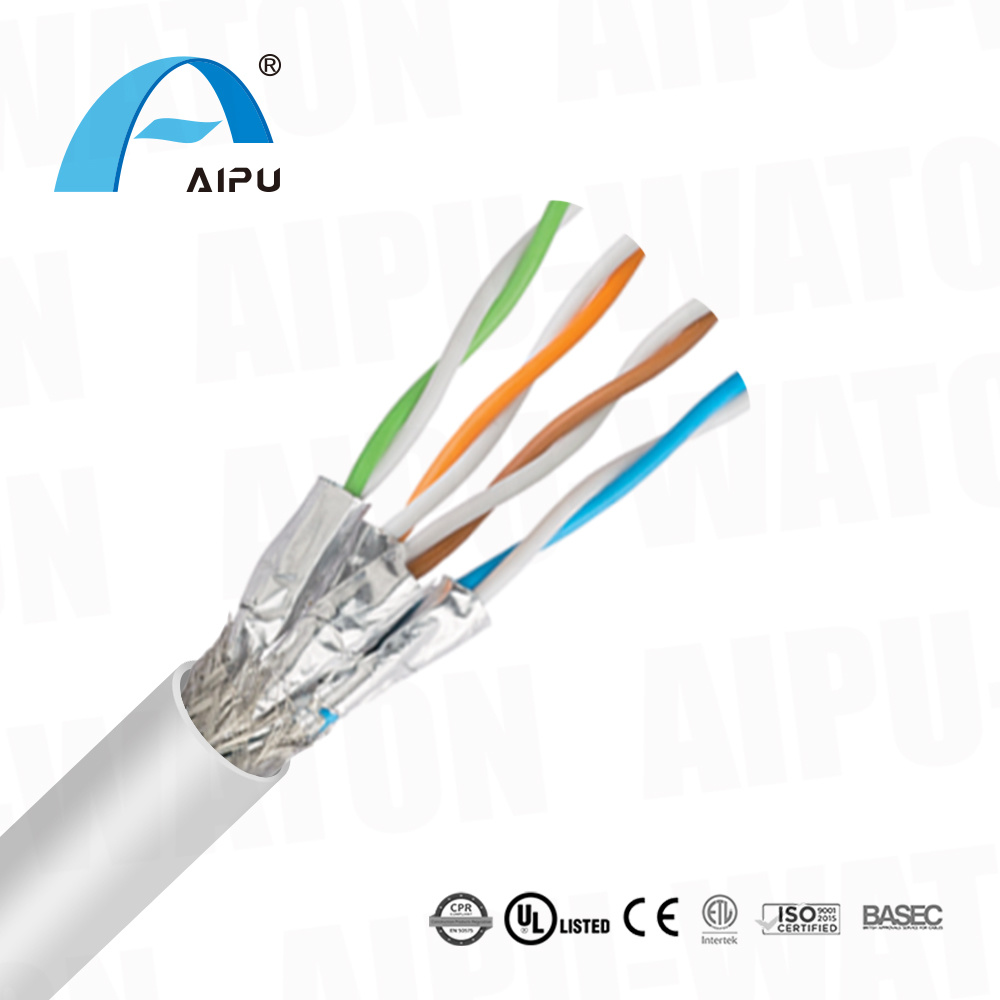

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for Popular Design For Elevator Cable - LiYcY Screened Multicore Control Cable – AIPU , The product will supply to all over the world, such as: Cannes, Jakarta, Nepal, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!