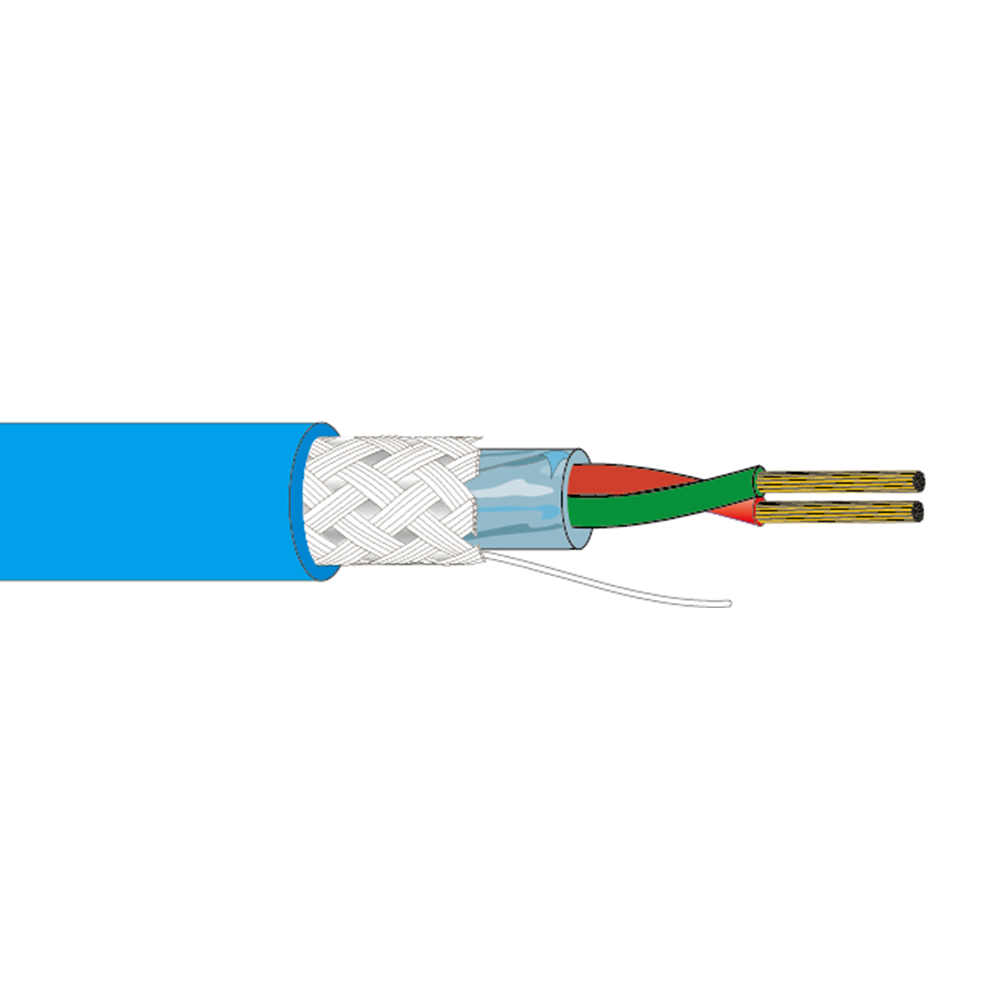

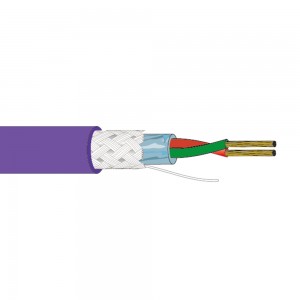

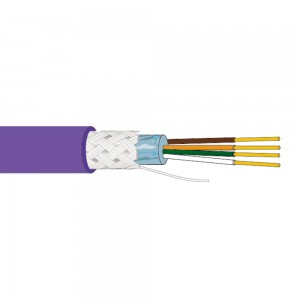

Siemens PROFIBUS PA Cable 1x2x18AWG

Constructions

1. Conductor: Solid Oxygen Free Copper (Class 1)

2. Insulation: S-PE

3. Identification: Red, Green

4. Filler: Halogen Free Compound

5. Screen:

● Aluminum/Polyester Tape

● Tinned Copper Wire Braided (60%)

6. Sheath: PVC/LSZH

7. Sheath: Blue

(Note: Armor by Galvanized Steel Wire or Steel Tape is upon request.)

Installation Temperature: Above 0ºC

Operating Temperature: -15ºC ~ 70ºC

Minimum Bending Radius: 8 x overall diameter

Reference Standards

BS EN/IEC 61158

BS EN 60228

BS EN 50290

RoHS Directives

IEC60332-1

Electrical Performance

|

Working Voltage |

300V |

|

Test Voltage |

2.5KV |

|

Characteristic Impedance |

100 Ω ± 10 Ω @ 1MHz |

|

Conductor DCR |

22.80 Ω/km (Max. @ 20°C) |

|

Insulation Resistance |

1000 MΩhms/km (Min.) |

|

Mutual Capacitance |

60 nF/Km @ 800Hz |

|

Velocity of Propagation |

66% |

|

Part No. |

No. of Cores |

Conductor |

Insulation |

Sheath |

Screen (mm) |

Overall |

|

AP-PROFIBUS-PA |

1x2x18AWG |

1/1.0 |

1.2 |

1.0 |

AL-Foil + TC Braided |

7.5 |

|

AP70001E |

1x2x18AWG |

16/0.25 |

1.2 |

1.1 |

AL-Foil + TC Braided |

8.0 |

|

AP70110E |

1x2x18AWG |

16/0.25 |

1.2 |

1.0 |

AL-Foil + TC Braided |

7.8 |

PROFIBUS PA (Process Automation) is used to monitor measuring equipment via a process control system in process automation applications. PROFIBUS PA runs at fixed speed of 31.25 kbit/s via blue sheathed two core screened cable. The communication may be initiated to minimize the risk of explosion or for the systems that intrinsically need safe equipment.