Well-Designed Multi Conductor Control Cable - CY Screened Multicore Control Cable – AIPU

Well-Designed Multi Conductor Control Cable - CY Screened Multicore Control Cable – AIPU Detail:

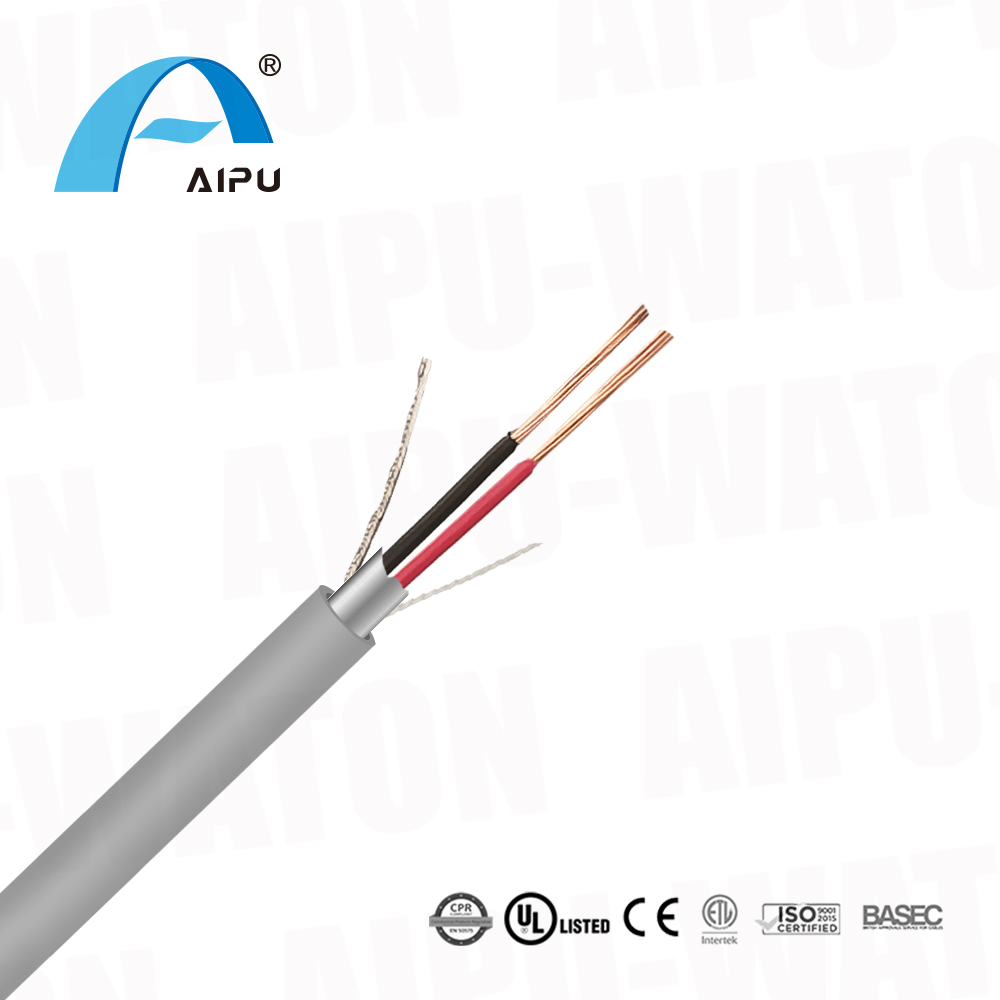

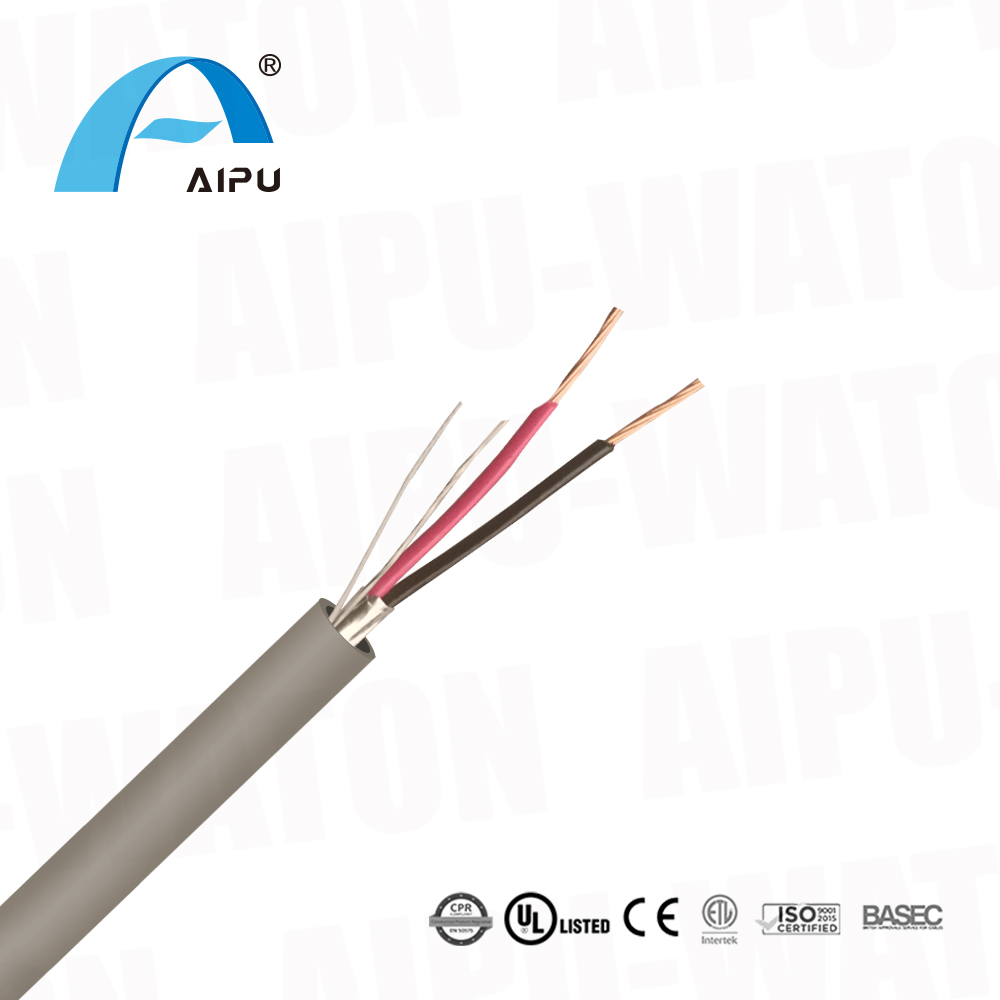

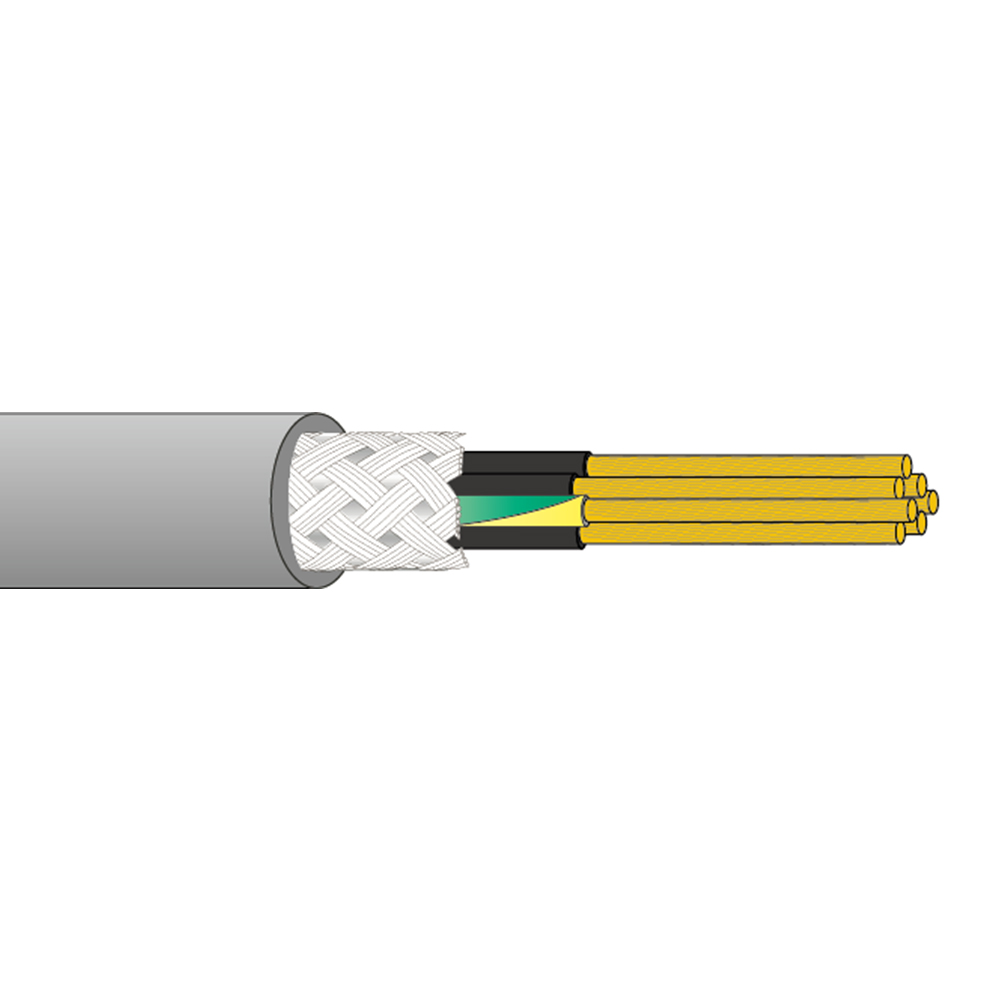

Constructions

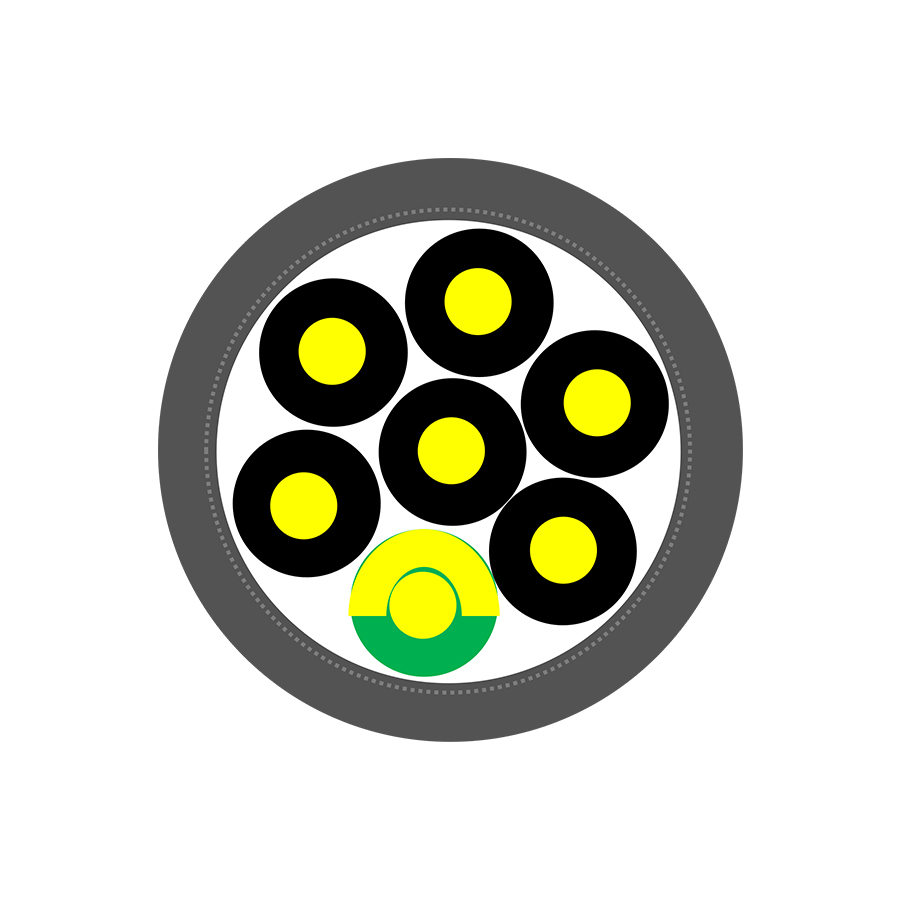

1. Conductor: Class 5 Oxygen Free Copper

2. Insulation: PVC/LSZH

3. Identification:

Black Cores with White Number

1pc Green/Yellow Core

4. Screen: Tinned Copper Wire Braided

5. Sheath: PVC/LSZH (Grey)

Installation Temperature: Above 0℃

Operating Temperature: -15℃ ~ 70℃

Rated Voltage: 300/300V

Reference Standards

BS6500

BS EN 60228

BS EN 50525-2-11

BS EN 50363-3

BS EN 50363-7

BS EN 50363-4-1

BS EN 50363-8

RoHS Directives

IEC60332-1

0.5mm2

|

Part No. |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.6 |

39 |

|

CY 3×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

5.9 |

39 |

|

CY 4×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

39 |

|

CY 5×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

39 |

|

CY 7×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

39 |

|

CY 8×0.5 |

16/0.20 |

0.4 |

0.8 |

TC Braided |

8 |

39 |

|

CY 10×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

0.6 |

39 |

|

CY 12×0.5 |

16/0.20 |

0.4 |

1 |

TC Braided |

9.9 |

39 |

|

CY 16×0.5 |

16/0.20 |

0.4 |

1.1 |

TC Braided |

11 |

39 |

0.75mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6 |

26 |

|

CY 3×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.3 |

26 |

|

CY 4×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

26 |

|

CY 5×0.75 |

24/0.20 |

0.4 |

0.8 |

TC Braided |

7.33 |

26 |

|

CY 7×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

26 |

|

CY 8×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

26 |

|

CY 10×0.75 |

24/0.20 |

0.4 |

0.9 |

TC Braided |

10.2 |

26 |

|

CY 12×0.75 |

24/0.20 |

0.4 |

1 |

TC Braided |

10.8 |

26 |

|

CY 16×0.75 |

24/0.20 |

0.4 |

1.1 |

TC Braided |

12 |

26 |

1.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.4 |

19.5 |

|

CY 3×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

6.8 |

19.5 |

|

CY 4×1.0 |

32/0.20 |

0.4 |

0.8 |

TC Braided |

7.3 |

19.5 |

|

CY 5×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.1 |

19.5 |

|

CY 7×1.0 |

32/0.20 |

0.4 |

0.9 |

TC Braided |

8.9 |

19.5 |

|

CY 8×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

9.8 |

19.5 |

|

CY 10×1.0 |

32/0.20 |

0.4 |

1 |

TC Braided |

11.2 |

19.5 |

|

CY 12×1.0 |

32/0.20 |

0.4 |

1.1 |

TC Braided |

11.7 |

19.5 |

|

CY 16×1.0 |

32/0.20 |

0.4 |

1.2 |

TC Braided |

13.1 |

19.5 |

1.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7 |

13.3 |

|

CY 3×1.5 |

30/0.25 |

0.4 |

0.8 |

TC Braided |

7.4 |

13.3 |

|

CY 4×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

8.2 |

13.3 |

|

CY 5×1.5 |

30/0.25 |

0.4 |

0.9 |

TC Braided |

9.1 |

13.3 |

|

CY 7×1.5 |

30/0.25 |

0.4 |

1 |

TC Braided |

10 |

13.3 |

|

CY 8×1.5 |

30/0.25 |

0.4 |

1.1 |

TC Braided |

11 |

13.3 |

|

CY 10×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

12.8 |

13.3 |

|

CY 12×1.5 |

30/0.25 |

0.4 |

1.2 |

TC Braided |

13.2 |

13.3 |

|

CY 16×1.5 |

30/0.25 |

0.4 |

1.3 |

TC Braided |

14.7 |

13.3 |

2.5mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 2×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

8.2 |

7.98 |

|

CY 3×2.5 |

48/0.25 |

0.5 |

0.9 |

TC Braided |

9.1 |

7.98 |

|

CY 4×2.5 |

48/0.25 |

0.5 |

1 |

TC Braided |

10.1 |

7.98 |

|

CY 5×2.5 |

48/0.25 |

0.5 |

1.1 |

TC Braided |

11.1 |

7.98 |

|

CY 7×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.2 |

7.98 |

|

CY 8×2.5 |

48/0.25 |

0.5 |

1.2 |

TC Braided |

12.8 |

7.98 |

|

CY 10×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15 |

7.98 |

|

CY 12×2.5 |

48/0.25 |

0.5 |

1.3 |

TC Braided |

15.6 |

7.98 |

|

CY 16×2.5 |

48/0.25 |

0.5 |

1.4 |

TC Braided |

17.3 |

7.98 |

4.0mm2

|

No. of Cores |

Conductor Construction (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Screen (mm) |

Overall |

Max. DCR (Ω/km) |

|

CY 3×4.0 |

56/0.30 |

0.6 |

1.1 |

TC Braided |

11.4 |

4.95 |

|

CY 4×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

12.4 |

4.95 |

|

CY 5×4.0 |

56/0.30 |

0.6 |

1.2 |

TC Braided |

13.5 |

4.95 |

|

CY 7×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

14.8 |

4.95 |

|

CY 8×4.0 |

56/0.30 |

0.6 |

1.3 |

TC Braided |

16.0 |

4.95 |

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Well-Designed Multi Conductor Control Cable - CY Screened Multicore Control Cable – AIPU , The product will supply to all over the world, such as: Milan, Oman, Iran, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!